|

Compressed Air Trams

By John Prentice |

|

Compressed Air Trams

By John Prentice |

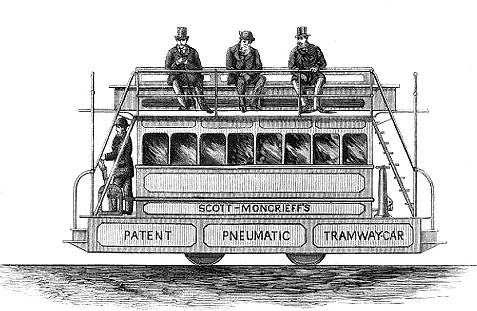

For a number of weeks in the middle of 1875 and at the beginning of 1877, Mr William Scott-Moncrieff carried out trials at Fairfield and on the Vale of Clyde line between Govan and Paisley Toll. His compressed air car was like a double deck horse tram of that era. It had six reservoir cylinders (below the floor, three each end) holding air at about 20 - 26 atmospheres, supplying 2 driving cylinders of 6 in. bore and 14 in. stroke, with pressure reduced to about 2 atmospheres before use. The wheelbase was 5 ft. The car weighed 6.75 tons unladen and 10.5 tons when in operation with 40 passengers. It would run for about 7 miles on each charge of air. It was built by Nielson & Co. at their Hyde Park Locomotive Works in Glasgow.

Mr Scott-Moncrieff stated that the car would run until the pressure in the reservoirs fell to about 7 atmospheres. Using 400-500 cubic feet of air per car mile, he calculated that a 150 h.p. compressor set would be enough to supply a service of 1,000 car miles per day at an all in cost (including staff. etc.) of 3d. to 4d. per car mile. The experiment was not continued and the Vale of Clyde went on to run a successful steam tram service from 1877.

Better known for its steam trams, the Wantage Tramway Company did undertake a trial of two Mékarski locomotives for three months from 5th August 1880, aided by Sir Frederick Bramwell and the Compressed Air Engines Company of 19 St. Swithin's Lane, London E.C. (who supplied the compressor set at Wantage terminus costing £2,000 and which charged 6 static reservoirs at 450 p.s.i.). Every day the locos each ran 4 return trips pulling one passenger car, and on special days 5 trips pulling two cars.

The locos had four reservoir cylinders, each 7 feet long by 2 feet 10 inches in diameter, charged with 30 kg of air at 30 atmospheres (450 p.s.i.), with the 'bouillotte' heating the air to 320 degrees F. The pressure at the driving cylinders was reduced to 60 or 70 p.s.i. One charge of air allowed the loco to do a return trip (5 miles and including a 1 in 47 incline) at which time the pressure had fallen to 5 atmospheres in three of the reservoirs and 27 atmospheres in the fourth (the reserve). Charging took about 15 minutes. The average speed was 9 m.p.h. and the total mileage per day for the locos was about 40 miles. Mr. George Stevenson, the line's engineer, estimated that the compressor used about 24 cwt of coal per day, but on such a sparse service this was far too high, as steam locos would only use 5 cwt per day.

On 9th November 1890, a few days before the trial was due to end, the two trams collided on the single track 100 yards from the Wantage terminus, with both locos being damaged but fortunately no persons injured. The experiment was not continued. The Compressed Air Engines Company also offered to demonstrate locos to Croydon tramways in 1880, presumably Mékarski locos, but the local authority refused permission. One of the Wantage locos was displayed at London's Victoria station for three days at the end of February 1881.

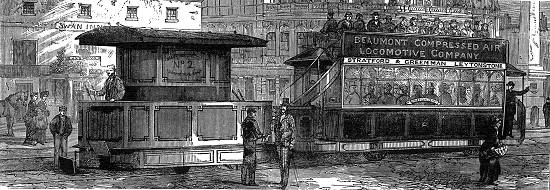

The NorthMet in London were always keen to try out new mechanical methods to replace horse trams, trying steam in 1877. In November 1879 Colonel Frederick. E. B. Beaumont of the Beaumont Compressed Air Locomotive Company, approached them with view to running his compressed air loco on their lines, when it was fully constructed. They agreed. In January 1880 they were also contacted by Mékarski offering a trial. The Mékarski proposal was referred to Beaumont, to see if he still wished to proceed. He did, and offered his loco at 6d per car mile. Beaumont had extensive experience in the use of air power in tunnel construction including the 1880 Channel Tunnel work, where he had hope to used compressed air locos had it been completed. He had also trialled such locos on London's Metropolitan Railway.

In February 1881 the compressor was installed at the Swan Yard depot. It had a compound steam engine using a 12 in. bore high pressure and a 20 in. bore low pressure cylinder fed from a boiler pressure of 95 lb. sq. in. The compressor was also a multi-cylinder staged system similar to that already described. Air was produced at the high pressure of l,000 lb. per sq. in. (66 atmospheres). It was fed from reservoir tanks by a 1.5 in. diameter iron pipe 250 feet long to a hydrant with flexible hose coupling at Stratford Broadway. Charging the car took 15 minutes, so the air car alternated with horse cars.

The loco was unusual in that it too used a compound engine driving the axles via gearing. The unit had four cylinders with volumes in the ratio 1, 3, 9, 27. As the reservoir on the car lost pressure each cylinder could successively be cut out and air applied directly to the next lower pressure cylinder thus retaining an overall constant power. The loco was built for Beaumont by Greenwood and Batley. It had two reservoir cylinders each 110 cubic feet.

A Board of Trade permit for one month was requested, but when the car arrived at Stratford depot on 17th August 1881, it was found to weigh 11 ton 6 cwt, and NorthMet would not agree to its use. Beaumont then agreed to supply a lighter one, which arrived in early October, a new B.O.T. permit being obtained for one month from 28th October 1881 after the inspection by Maj. Gen. Hutchinson. Beaumont No. 2 was similar to No. 1 but had two sets of two compound cylinders (2.75" and 10" diameter), a 65 cu. ft air reservoir, and was said to have a steam jacket surrounding the cylinders to prevent cooling, fed from a tiny coke boiler at the rear of the engine using exhausted air for a forced draught. It weighed 8.5 ton and pulled a horse car which would have weighed about 4 tons laden. Maj. Gen. Hutchinson commented that the car had no governor or speed indicator.

The trials were carried out on the route from Stratford to the 'Green Man', Leytonstone, a 2.5 mile double track line with a rise of 82 feet, a maximum gradient of 1 in 25 and a tightest curve (at Maryland) of 50 foot radius. On one trial it was stated that with an initial pressure of 1,000 lb. at Stratford, it had fallen to 675 lb. at Leyton and to 550 on its return (downhill). A variable cut-off was used on the engine to counter the fall in pressure. Fuel consumption was estimated at 23 lb. per car mile but that this would reduce 9-10 lb. for a full multi-car system with 4 locos. In November Beaumont requested a further months B.O.T. permit and offered to operate a 5 year contract on the line at a revised price of 7d per car mile and repeated that offer in December 1881. NorthMet however did not take up the offer, but went on to try battery trams.

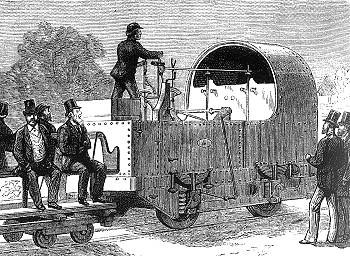

This artist's engraving shows the Beaumont locomotive at the Woolwich trial.

This artist's engraving shows the Beaumont locomotive at the Woolwich trial.

In 1881 experiments with compressed air locomotives took place in the Royal Arsenal at Woolwich and it is thought that the Beaumont loco used was based on his No. 2 tram engine, and was compared with loco works number 761 from Manning Wardle.

Note: It has been stated (Charles Klapper: 'Golden Age of Tramways':1961) that Beaumont also tried his cars on the Portland Road route of the Croydon & Norwood Tramways based on the fact that a suitable compressor as found in the 1920's at the String Lane, Woodside depot site. However Geoffrey Baddeley in 'Tramways of Croydon' (Second edition 1982), feels that this compressor was in fact used for Hohenzollern fireless steam locos, a view with which the current writer agrees as he has found no mention of Beaumont cars on London tramways other than the NorthMet.

Sir Frederick Bramwell, who we have heard visited Nantes, brought the Mékarski design to Britain (see Wantage) and set up the British Mékarski improved Air Engine Co. Ltd, to utilise Mékarski's patents. Together with H. G. Harris he designed a car similar to a horse car but higher on its trucks. It had a 38 seat double deck open top body with knifeboard seats upstairs and was probably built by the Lancaster Wagon Company with running gear by Clayton & Co. of Preston, Lancs.

The tram had steel channel frames and two cylinders driving one of the two axles, each cylinder having 5.125 in. bore and 10 inch stroke. Air was stored in nine cylinders mounted longitudinally below the floor, 6 large main ones at the ends and three smaller reservoirs between the axles. This car was described in the September 1882 edition of "Engineering" and a drawing of it is reproduced here, courtesy of E.R.Oakley.

Air was supplied at 30 atmospheres from a compressor set and storage tanks at the Holloway Road end of Caledonian Road, and it was on the Caledonian Road that the trials took place

Air was supplied to the cylinders via a regulator at 3 to 6 atmospheres. The cylinders were enclosed by side panels as in the French cars. The 'bouillotte' (or 'hot-pot' as it was described in 'Engineering') was fitted, but as this car was double ended, there were two, one at each end, the driver transferring the regulator hand wheel and reversing lever between ends at the termini. Entry to the car was at the ends from between the rails as on the Nantes cars. The car was fitted with both a speed indicator and a governor (set to about 10 m.p.h.) and the brakes could be applied either from this governor, by a foot pedal, or by air pressure. The car could run about 10 miles (or two return trips) per charge of air. It weighed 6.5 ton unladen and about 9 ton loaded.

Maj. Gen. Hutchinson inspected the line and works for the Board of Trade on 16th March 1882 but the tram was not ready until 2nd February 1883, so he visited the line again on 18th May 1883 when he issued a three month licence, and although happy with the set-up felt that the controls and tops of the bouillottes should he caged in to stop tampering or passengers getting burned. Of course on the original single-ended French cars, the passengers had no access to the driving position so this problem had not previously occurred. The licence was renewed for a further three months on 7th August 1883 and again on 17th November 1883 for one year with the proviso that any new cars were inspected.

In the Preston Chronicle, dated 9th August 1884, it was stated that parts and castings for London compressed air cars were being constructed at Joseph Clayton's foundry (probably for four cars), and on 4th July 1885 another report stated that bodies were being constructed at the Lancaster Wagon Company works for compressed air cars for use at Holloway, London, one of which was at work in the grounds of the South Kensington Inventions Exhibition alongside Blackpool conduit car 6.

On 13th August 1887 an inspection of new cars at Warlers Road depot was requested but B.O.T. stated that since it was four years since the last request this was not a renewal but a new request, and the company had to re-apply to the local authorities for permission. Maj. Gen. Hutchinson re-inspected the line on 14th February 1888 and issued a licence for six months for up to six cars (it is thought there were 5). After that period the service ceased.

Colonel Beaumont was involved with the construction of the Mersey Railway tunnels under the river in Liverpool, and in 1883 suggested to the Liverpool United Tramways that he could operate a horse tram route using his compressed air tram at the cost of 3d per car mile. The company agreed to trials at Beaumont's expense and on 5th November 1884 the Board of Trade inspected the tram, passing it fit for public service.

The specification suggests that the locomotive used in the tests was based on the same Beaumont No. 2 engine built by Greenwood and Batley, that had been used for the Northmet trials. The trailer was also probably the Northmet one. It was certainly taller than a Liverpool United horse car, as restrictions were put on it carrying passengers on the upper deck on parts of the route with low bridges such as Strand Road.

The 1,000 p.s.i. compressor set was installed in the Rimrose Road Depot stables in Bootle. Trials were undertaken from there by running along Derby Road to Sandhills Lane and returning via Stanley Road and Strand Road. On 4th March 1885 the owner of the track, Bootle Corporation, complained that the tram was damaging the track joints and trials were suspended until the beginning of June.

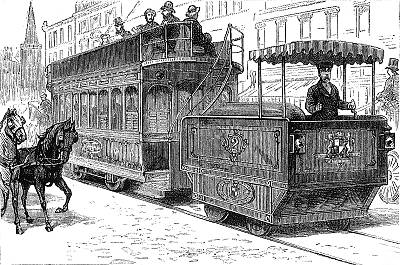

This artist's engraving shows a Beaumont locomotive pulling a horse tram and was probably the Liverpool trial.

This artist's engraving shows a Beaumont locomotive pulling a horse tram and was probably the Liverpool trial.

After these initial tests, Liverpool Corporation granted permission for an extension over their tracks into the city running round on Tithebarn Street, Moorfields and Hatton Garden. In 1886 a further extension was requested to reach Lime Street and Mount Pleasant, but since this required extra pointwork to turn the car there, which the Corporation said would have to be paid for by the United Company, this did not proceed and soon after the trials ended. The costs of running the air tram had exceeded expectations.

At the Antwerp World Fair in 1885 Beaumont demonstrated one of his compressed air engines, possibly one of these Liverpool units, where it was compared with steam and battery trams to decide the best stored up force for public transport.

On 3rd November 1886, an Edward Mein of Liverpool was granted a German patent for a compound compressed air tramway motor which was probably inspired by the Beaumont trials, but nothing more was heard of this.

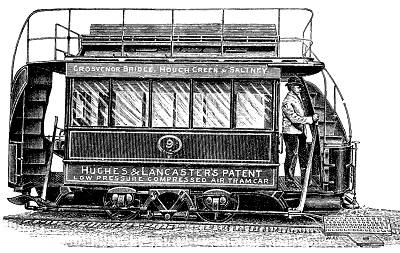

One of Chester's small double deck Starbuck horse cars (number 9, but shown on the drawing as 10) was purchased by Hughes and Lancaster of Ruabon in 1886 and was fitted with low pressure air equipment for tests. It had 4 underfloor wrought iron driving cylinders with 5 in. bore and 3 in. stroke which used 30.5 pounds of air per car mile on the level. Air was used at the lower pressure of a maximum of 9 atmospheres. The theory is that by using lower pressures the losses due to heating on compression and cooling on use are much reduced. In practice such cars were under powered and had a short range.

From their publicity material, this engraving shows Hughes and Lancaster car 9 in its double deck form during early testing in Chester.

From their publicity material, this engraving shows Hughes and Lancaster car 9 in its double deck form during early testing in Chester.

The test car was briefly operated over the Chester system, but leakage accounted for more air use than traction, and the car could only manage one slow 2 mile trip on the level for each charge. It ran on the route from Saltney to Grosvenor Bridge. Around 1890 the car was cut down to single deck.

In 1888 John Hughes filed a patent for this type of tram which stored the air in a tubular structure which would also form the framework of the car. It mentions the option of laying a cast iron pipe beside the tracks so that the car could be recharged at stops (taking 15 to 40 seconds) as tried in Chester, but specifically includes a method where the car could pick up air while actually in motion from automatic valves beside the rails.

In 1891 Hughes and Lancaster offered to work the steam tramway of the Birmingham & Midland Tramways Company, which operated from Birmingham to Dudley, using air cars of this type for a 12 month trial on acceptable terms. Birmingham & Midland passed the request to Birmingham Council for permission to use their tracks in the city area, and to lay a 4" diameter air supply pipe under the footpath parallel to the tramway with connections to valves between the tracks. The council agreed, subject to terms for removing the equipment and restoring the footpath afterwards. However, nothing further happened and the idea seems to have been dropped.

According to Tramway and Railway World for February 8th 1900, on January 8th of that year, the "British Compressed Air Tramways Company" was registered with a Capital of £75,000 in £1 shares, to acquire and develop patents and concessions for compressed air tramways and railways, together with other tramway related activities. The signatories were all based in London. As one would expect this late in electric tramway progress, nothing further was heard of the company.

![]() Go now to Next Section

Go now to Next Section

![]() Return to Index

Return to Index