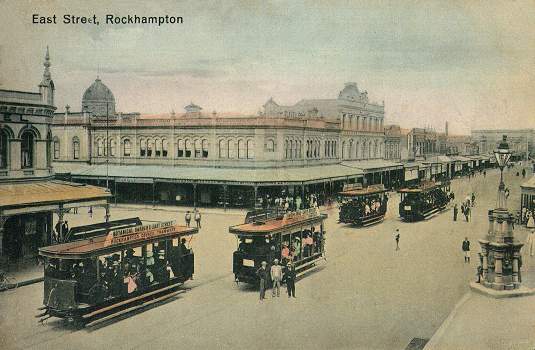

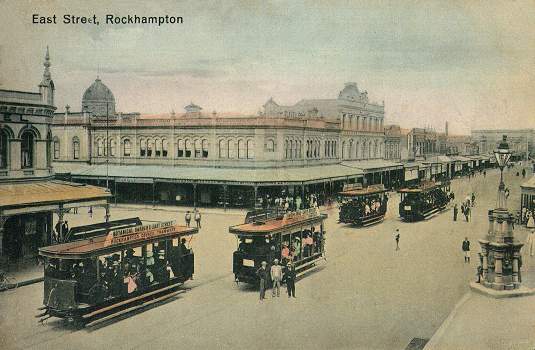

From 5th June 1909, originally with four French Purrey steam trams, the Rockhampton City Council of Queensland, Australia operated a six and a half mile tramway built to 3ft. 6in. gauge. At termini there were turning circles, as the trams were single ended and pulled up to two trailers. Ultimately nine Purrey cars were owned, with the Queensland Government Railway having two similar cars. The wooden bodies of both trams and trailers were single-deck open sided.

The trams were designed by Valentin Purrey, a mechanical engineer and constructor of Rue Saint-Lazarre, Paris (by 1907 Boulevard J.J. Bose, Bordeaux). They had two cylinder simple engines with chain drive. But the truly unique feature was the steam generator (also used on steam lorries), which was to a design patented by Purrey and used extensively on Paris trams from 1897. The generator was designed to provide a vehicle which had low weight for use on light trackwork, was silent and emitted no fumes, but at the same time was as easy to drive as an electric tram since the boiler operation was automatic.

The whole steam generator was housed in a sheet metal rectangular box. At the top was a riveted steel cylinder which contained water with space above for steam collection. At the bottom was a cast iron rectangular box divided into unconnected upper and lower sections, the upper for steam, the lower for feed water. The top cylinder and the water section of the lower box were connected by two cast iron columns of 35mm bore, which allowed water to pass between them and which were outside the heated area of the unit. Water from the lower box flowed into 30 steel boiler tubes of 13mm bore (18mm o/d) which were about 4.5 metres long and were bent eight times in a zigzag inside the fired area, and steam produced was collected in the top cylinder. From there eleven similar tubes returned through the heated area to deliver superheated steam to the steam area of the lower box, from where it fed the engine. The bottom sections of the tubes were protected from the direct flames below by a metal or asbestos shield.

The whole steam generator was housed in a sheet metal rectangular box. At the top was a riveted steel cylinder which contained water with space above for steam collection. At the bottom was a cast iron rectangular box divided into unconnected upper and lower sections, the upper for steam, the lower for feed water. The top cylinder and the water section of the lower box were connected by two cast iron columns of 35mm bore, which allowed water to pass between them and which were outside the heated area of the unit. Water from the lower box flowed into 30 steel boiler tubes of 13mm bore (18mm o/d) which were about 4.5 metres long and were bent eight times in a zigzag inside the fired area, and steam produced was collected in the top cylinder. From there eleven similar tubes returned through the heated area to deliver superheated steam to the steam area of the lower box, from where it fed the engine. The bottom sections of the tubes were protected from the direct flames below by a metal or asbestos shield.

At the base of the unit, below the boiler tubes, was the firebox with walls of fire brick and an inclined grate. There was a heating surface of 6.78 square metres and a grate area of 2.49 square metres. Coke was fed to the grate by gravity from a hopper fixed to the side of the unit. The fire had an automatic damper, operated by the steam pressure in the upper cylinder, excessive pressure pushing on a small piston which closed the ash-pit door and reduced the draft. Smoke escaped through a chimney at the top of the unit.

Water was fed to the lower box by a pump continuously driven by an eccentric on the front axle of the vehicle. When stationary for long periods, a small steam donkey engine, which could also be worked manually, could top up the water supply. A float in the top cylinder caused a valve to open and close which diverted the feed water either into the boiler or back into the storage tanks. These contained 500 litres of water and were under the seats of the tram. Water was filtered through granulated charcoal before use. Safety valves were fitted and the boiler was tested to 20kg/cm2, but steam pressure was normally maintained at 15kg/cm2. The generator weighed 1.46 tons.

(Note: The preceding figures and description are based on the specification of the Purrey steam generators used on Paris trams - see Postcard.)

Our postcard by an unknown publisher but printed in Germany and posted in September 1914, shows the original four Purrey trams on East Street, Rockhampton. One Rockhampton Purrey tram was reconstructed in 1988, using some original parts, and still runs at the Archer Park Steam Tram & Station Museum in Rockhampton.

![]() Go to Postcard Of The Month Index

Go to Postcard Of The Month Index